Mechanical Misadventures

I'm not a "car guy," but I love my car. I have a stock Subaru Impreza hatch back. This car got me through high school, college, and my first job. That's twelve years, and counting. And, I'm not done counting yet.

In March, 2020, just as the shelter in place orders were going into effect, my shifter stopped working. It happened suddenly; I was travelling back to San Diego after visiting my parents. It's a 300 mile drive from SLO to SD, and at the second to last stoplight I couldn't get into gear. Eventually I got into second and managed to grind into my apartment without stopping. But now what?

I am mechanically inclined enough to do basic car maintenance. I grew up changing my own fluids, brake pads, and once a brake rotor, but I was out of my depth when it came to this. I have never worked on a transmission, and I had no clue how to even diagnose what was going on. So, like any good Millenial, I turned to the internet. Searching forums and Googling my symptoms I came up with a list of potential problems. After I figured out that the clutch hydrolics weren't the culprit the only other solutions involved dropping the transmission. At this point I was left with two options:

- tow my car to a shop and have a professional do the work, or

- roll up my sleeves and do it myself.

One of the best parts about living in the information age is that you can find anything on the internet. YouTube saved my bacon several times during this project. It is amazing how many people put out great tutorials online. Especially since Subaru charges $35 to rent their factory service manual for 72 hours! I have a lot of respect for the professionals who put their knowledge online for kludges like me to use. You can find a list of my resources at the bottom of the page.

I don't want this page to be a boring list of technical details, so I'll finish up with a few of the lessons I learned.

Lesson 1 - Car work isn't that hard

Auto maintenance has always been an enigma to me. I was never taught how to work on my car, and for the most part they just work. Taking on this serious of project was incredibly daunting at first, but as I got my hands dirty things started to make sense. The biggest takeaway is this: As long as you have time, patience, and the internet anything is possible.

Lesson 2 - Buy the tools you need

Like I said before, I am cheap and stubborn; here is the perfect illustration: I don't have torque wrenches, instead I use a steel pipe and a luggage scale. I can't tell you how many times I dropped my socket wrench before my neighbor lent me his torque wrenches. Thanks to Justin I saved a lot of time and energy (and I now own my own torque wrench.)

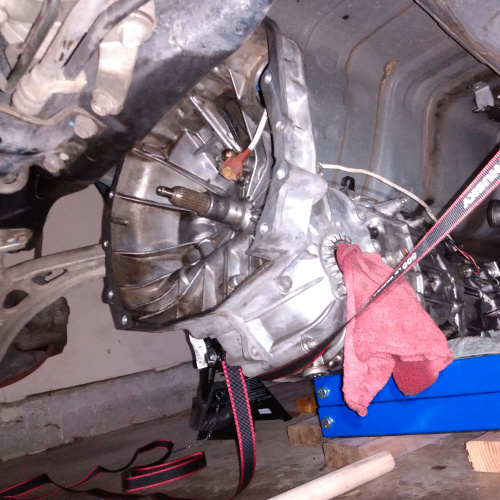

Also, the only jack I could get shipped to my apartment was a motorcycle lift. This did the trick, but a transmission jack would have made the job much easier. With my setup I had to roll the transmission into place with wooden dowels and guide it with rachet straps. It would have been a lot less sketchy if I had the right jack.

Lesson 3 - When a professional says you can finish a job in 8 hours...

...it will probably take you 3 times that. It took me 27.5 hours from first bolt off to test drive. This was spread out over 8 days and does include set up and break down time, but I still spent three times longer than BriansMobile1 said I should. And this doesn't count time researching or going to the store.

Lesson 4 - Always label everything

The last thing you want at the end of a project like this is to have three extra screws.

Lesson 5 - 6 point wrenches are far superior to 12 point wrenches

Do not use 12 point wrenches on old bolts. You will wind up busting them.

The total final cost of the parts and extra tools I bought came out to $647, less than half the cheapest quote I found. This isn't a project I want to take on again soon, but I'm glad I did it. Thankfully my car has been running for a month with no more problems.